POCONO – Monadnock Non-Wovens, the US manufacturer of meltblown roll goods, has launched a new line of high performance nonwoven fabrics for the air filtration sector.

The new enhanced filter media, Monadnock HPAQ 3F, is said to be engineered specifically for respirators, HVAC and air purification filters.

Monadnock says that increased risk and concern over health and well-being are driving innovation in air filtration for residential, commercial, industrial, and agricultural spaces.

High levels of precision and purity are crucial in many fields and applications, particularly where even the smallest impurities can have significant consequences.

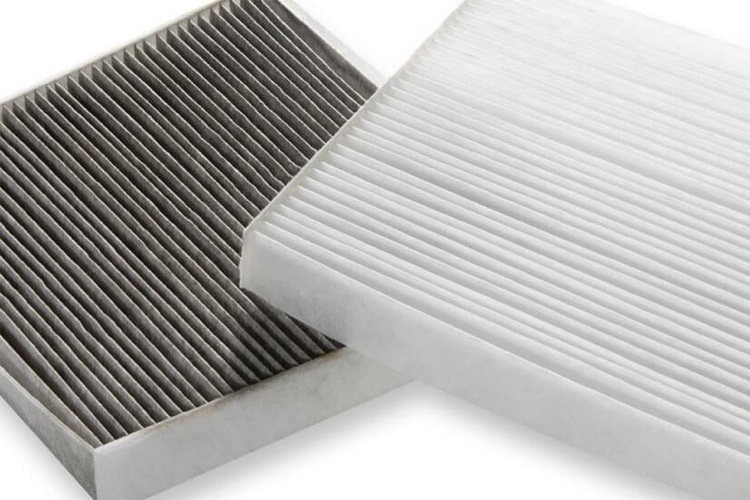

Filters made with Monadnock HPAQ 3F are designed to capture more dust, pollen, allergens, viruses, and smoke with lower pressure drop than traditional polypropylene and other synthetic meltblown media.

They will also meet all international filtration standards including ASHRAE 52-2, ASTM 2100, EN-149, HEPA, MERV 10-16, and NIOSH.

Jim Cree, MNW president, explained: “Bringing this new capability to our manufacturing facility enables us to produce materials that help meet global air filtration standards.

“In a time with forest fires and airborne diseases, we are offering the filtration market a healthier solution that is made right here in the United States.”

HPAQ 3F is available in rolls up to 95 ins / 2.4 m wide. This virgin polypropylene (PP) product is recyclable, and trim waste also can be repurposed in sorbent applications. As with all MNW products, it is made with 100% renewable wind-powered electricity (Green-e certified RECs).