Aphios Corporation, based in Woburn, Massachusetts, has secured a new patent which could have significant implications in the further development of cellulosic biomass as the basis for new fibres, nonwovens and other products.

Aphios Corporation, based in Woburn, Massachusetts, has secured a new patent which could have significant implications in the further development of cellulosic biomass as the basis for new fibres, nonwovens and other products.

United States Patent No. 8,540,847 – ‘Methods and Apparatus for Processing Cellulosic Biomass’ – describes the company’s Aosic enabling technology platform.

Cellulosic biomass resources are currently greatly underutilised around the world and if effectively exploited, could reduce climate change while alleviating several energy and environmental problems.

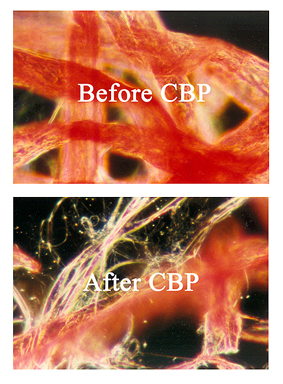

“Cellulosic biomass is tightly wound for obvious mechanical strength reasons,” says Dr Trevor P. Castor, inventor of the Aosic platform. “In order to breakdown cellulose into its individual sugar molecules, cellulosic biomass must be expanded to enhance the access of enzymes that cleave the polymeric bonds between individual sugar molecules.”

Currently, steam explosion is the most commercially used method for expanding cellulosic fibres. However, this process has several disadvantages, including degradation of cellulose and hemicelluloses at the high temperatures utilised and the generation of byproducts that are toxic to cellulosic degrading enzymes. As a result, stem explosion-treated wood must be washed after pretreatment. The process is thus both water and energy intensive.

In the Aosic process, biomass is contacted with SuperFluids such as carbon dioxide with or without small quantities of polar cosolvents such as ethanol, both sourced from the downstream fermentation process. Pressure is released and fibres are made more accessible to enzymes as a result of expansive forces of SuperFluids (about 10 times those of steam explosion) and carbonic acid hydrolysis. Additional fibre separation is achieved by ejecting biomass through mechanical impact devices. Carbon dioxide is recovered and recycled and the pressure energy is recovered in a turbine.

“Carbon dioxide is consumed in the Aosic process which is a net consumer of carbon,” says Dr Castor. “It also utilises significantly less water than steam explosion and the dilute acid pre-hydrolysis pretreatment process. It can be used for wood cuttings, bagasse, newsprint, corn fodder and spent biomass from the manufacturing of natural pharmaceuticals and nutraceuticals.

“While the primary potential application is pretreating biomass waste for conversion into ethanol and other wood-based chemicals, there are several other potential applications such as newsprint recycling.”