CARY – Among speakers at the upcoming INDA RISE (Research, Innovation and Science For Engineered Fabrics) conference, will be Tobias Wagner, research and development manager at Reicofil, who will outline the improvements in spunmelt nonwoven production that are possible with the company’s latest RF5 technology.

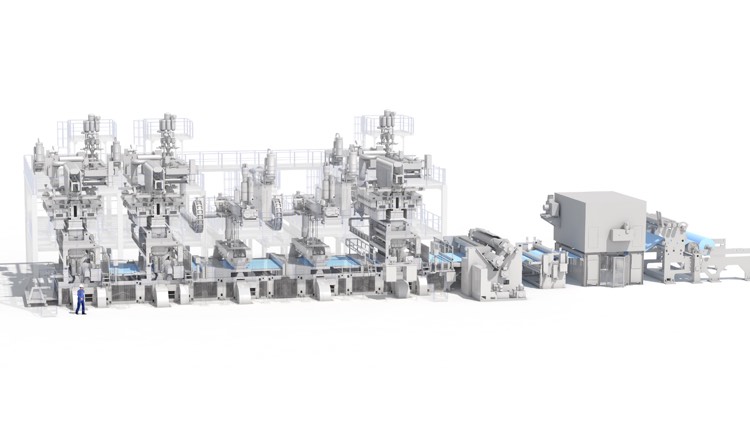

The RF5 platform combines high throughput with the lowest defect rates and the inline recycling of edge trims and scrap rolls to minimise waste during production.

The line also enables the production of fine bicomponent fibres for maximised specific tensile strength, enabling the downgauging of products such as replacing a standard 45gsm SMMS medical nonwovens with a 35gsm alternative. The system enables the production of spunbonds down to a weight of 6gsm.

In addition, the latest machine generation is equipped with energy efficient components to provide the lowest specific energy consumption, reducing converting costs from the resin to final nonwoven, and new software applications enable reproducibility with the lowed defect levels.

RF5 XHL technology meanwhile takes softness to a new level, by employing a special patented bicomponent fibre system in which two resins are combined in a new eccentric core/sheath cross-section to create optimal crimp at a reduced fibre size.

Standard calendered webs use a bonding pattern with a distinct visual mark but with XHL technology a web with low visual impact is produced for a uniform visual appearance free of optical distortions. This improves the tactile properties of the web compared to standard patterned products with higher impact to the web structure, and also enabled a downgauging approach to be taken, achieving necessary product properties with lower basis weights.

The RISE conference takes place at NC State University in Raleigh, North Carolina, from September 26-27 and the full programme can be viewed here.