TROISDORF - Reifenhäuser has launched a new digital solution for carbon footprint calculations, which will allow nonwovens producers to see how the carbon footprint changes in ongoing production and identify how they can reduce their emissions.

Unveiled at this week's K 2022 exhibition, the Carbon Footprint Dashboard is said to contribute both to climate protection and to economic success, with a CO2 reduction usually also accompanied by savings in energy and raw materials.

Carbon footprint calculation for manufacturing companies is quite complex and starts with the different methods of calculation - at the company level, but also at the product level. The corporate carbon footprint (CCF) balances the CO2 footprint for the entire company - from energy procurement to production to the vehicle fleet. The product carbon footprint (PCF) records all CO2 emissions that occur along the life cycle of a product, i.e. from raw materials to production and use to disposal.

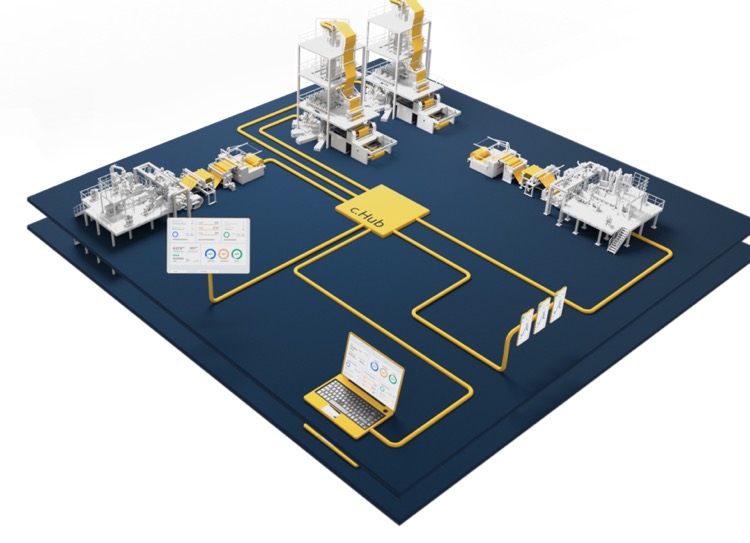

The prerequisite for the carbon footprint calculation is the standard version of Reifenhäuser's digital solution ExtrusionOS & c.Hub Middleware and the availability of the required data.

"The Carbon Footprint Dashboard shows the different emission sources over the production period," explained Dr. Tim Pohl, Director Sustainability and Business Development at the Reifenhäuser Group. "In the basic version, assumptions are made about the carbon footprint of the raw materials used and the calculation is based on the energy mix of Europe, for example. This is sufficient to determine initial potential for carbon footprint reduction. If more precise information is required, we can customize the calculation according to local conditions. Such a calculation becomes exciting when in-house recycled material is used."

Manufacturers of films and nonwovens can therefore approach the topic of calculation "bottom-down" via a corporate carbon footprint, or they can do it "bottom-up" via a product carbon footprint for each of their products. The latter is ideal if a broad product portfolio with different raw materials and recycled content is processed. For this purpose, a customer-specific carbon footprint dashboard can be created in Reifenhäuser's ExtrusionOS software solution.

From an economic point of view, the carbon footprint calculation also allows producers to show the carbon footprint to third parties and therefore certify a particularly sustainable product series, for example. This, says Reifenhäuser, potentially opens up new sales markets and increases economic success while the savings in energy and raw materials pay off, especially in view of the current high purchase prices.